| Product | Titanium Zirconium Molybdenum Wire (TZM Wire) |

|---|---|

| Part Number | TRM-MO013 |

| Standard | ASTM B387 TYPE 364 |

| Surface | Grinding, Chemical cleaning or Black |

| Density | 10.22 g/cm3 |

Titanium Zirconium Molybdenum Alloy is so-called TZM alloy, and it refers to the molybdenum- 0.5% titanium- 0.1% zirconium alloy. This alloy has better welding performance and higher strength/hardness. TZM wire is made from metal powder, pressed into ingots, sintered, and then swaged and drawn down to the required dimension. TRM can offer TZM wire in various dimensions. Please contact us for more details.

Application: TZM wire is used as high-temperature furnace components, plastic injection molding nozzles, casting molds, rotating anodes, etc.

Order Information

Please include the following information with your inquires and orders:

1. Quantity in weight, or the number of pieces

2. Dimensions

3. Surface Requirement or Application

Assay

| Element | TYPE 364 |

|---|---|

| C | 0.01-0.04 wt% |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.005 wt%, max |

| Ti | 0.4-0.55 wt% |

| Zr | 0.06-0.12 wt% |

| Mo | Remainder |

Typical Size Available (Please inquire for details)

| Diameter, In. | Length, In. Max. |

|---|---|

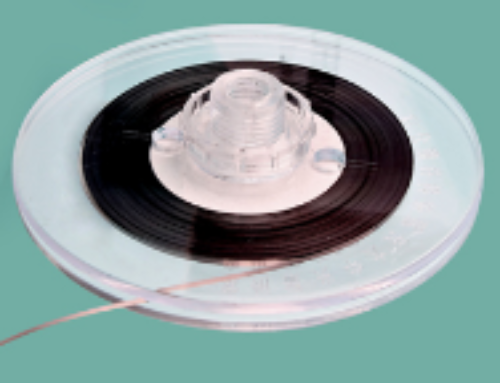

| 0.008”-0.2” | L (In Coils or On Spools) |

Please refer to the TZM Rod for larger sizes.

Mechanical Properties– ASTM B387 TYPE 364

| Diameter, in. (mm) | Tensile Strength,min, ksi (MPa) | Yield Strength, min, ksi (MPa) | Elongation min,% |

|---|---|---|---|

| 3⁄16 to 7⁄8 (4.76 to 22.2) | 115 (790) | 100 (690) | 18 |

| 7⁄8 to 1 1⁄8 (22.2 to 28.6) | 110 (760) | 95 (655) | 15 |

| 1 1⁄8 to 1 7⁄8 (28.6 to 47.6) | 100 (690) | 85 (585) | 10 |

| 1 7⁄8 to 2 7⁄8 (47.6 to 73.0) | 90 (620) | 80 (550) | 10 |

| 2 7⁄8 to 3 1⁄2 (73.0 to 88.9) | 85 (585) | 75 (515) | 5 |

Materials available for Molybdenum and Molybdenum Alloy Wire

Type 361 – Unalloyed powder metallurgy molybdenum.

Type 364 – Powder metallurgy molybdenum- 0.5% titanium- 0.1% zirconium (TZM) alloy.

Standard Packing

In Coils or On Spools, loaded in Wooden Boxes or Carton Boxes.

| Physical Properties | TZM |

|---|---|

| Phase | Solid |

| Melting Point | 2617°C |

| Boiling Point | 4612°C |

| Thermal Conductivity | 126 W/m.K |