| Product | Molybdenum Wire (Mo Wire) |

|---|---|

| Part Number | TRM-MO004 |

| Standard | ASTM B387 TYPE 361 (Purity:99.95%) |

| Surface | Black or White |

| Density | 10.2 g/cm3 |

| CAS# | 7439-98-7 |

Order Information

Please include the following information with your inquires and orders:

1. Quantity

2. Dimensions

3. Surface Requirement or Application.

Assay

| Element | TYPE 361 |

|---|---|

| C | 0.01 wt%, max |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.01 wt%, max |

| Mo | Remainder (99.95% min.) |

Typical Size Available (Please inquire for details)

| Diameter,In. | Length, In. |

|---|---|

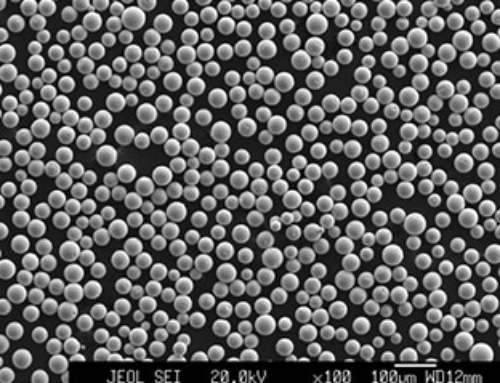

| On Request | In Coils or On Spools |

Please refer to Mo Rod for larger sizes.

Application

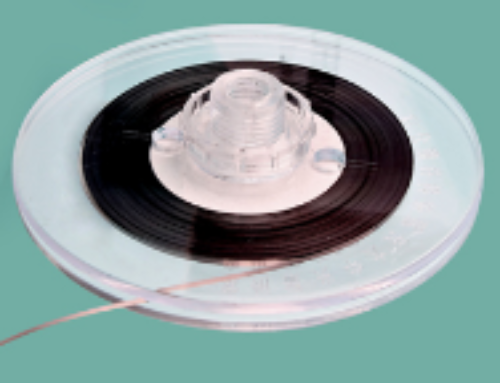

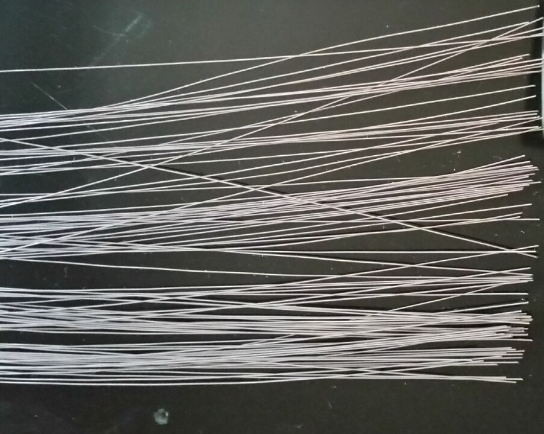

Black Molybdenum wire

The surface is black with the graphite coating. It is used for making heat parts of the electronic vacuum device, hooks, cored wires, and etc.

White molybdenum wire

The surface is bright without the oxidation. It is used for wire cutting machines, producing electric vacuum components.

Spray molybdenum wire

The surface is covered with graphite. It is used for the Thermal Spraying. Thin layers of molybdenum are thermal sprayed on surfaces of the parts to increase their abrasion resistance.

Materials available for Molybdenum and Molybdenum Alloy Wire

Type 361 – Unalloyed powder metallurgy molybdenum.

Type 364 – Powder metallurgy molybdenum-0.5% titanium-0.1% zirconium (TZM) alloy.

Standard Packing

In coils, on spools or reels, packed in Wooden Boxs or Carton Boxs.

| Physical Properties | Molybdenum (Atom#42) |

|---|---|

| Phase | Solid |

| Melting Point | 2896 K (2623°C, 4753°F) |

| Boiling Point | 4912 K (4639°C, 8382°F) |

| Heat of Fusion | 37.48 kJ/mol |

| Heat of Vaporization | 598 kJ/mol |

| Molar Heat Capacity | 24.06 J/(mol•K) |

| Atomic Weight | 95.95 |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |