| Product | Molybdenum Rod (Mo Rod, Mo Bar) |

|---|---|

| Part Number | TRM-MO003 |

| Standard | ASTM B387 TYPE 361 (Purity: 99.95%) |

| Surface | Grinding, Chemical cleaning or Black Oxide |

| Density | 10.2 g/cm3 |

| CAS# | 7439-98-7 |

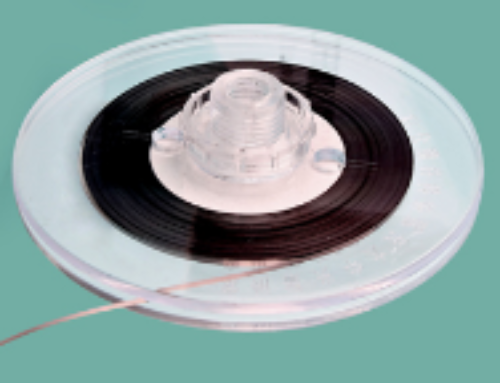

Molybdenum rod, or the Molybdenum bar, are any straight product with a round, rectangular, hexagonal, or octagonal solid cross section, 4 in. (101.6 mm) in diameter or less, or of equivalent cross-sectional area. We can offer molybdenum rods in various dimensions with purity up to 99.95%. Please contact us for more details.

Application: Used for the steel additives, the welding electrodes and the furnace heating elements, and etc.

Order Information

Please include the following information with your inquires and orders:

1. Quantity

2. Dimensions

3. Surface Requirement or Application. Surface can be supplied in:

- Cleaning- surface is chemically cleaned to remove all lubricants and oxides.

- Black Oxide- surface is either as swaged or as drawn and retains a coating of processing lubricants and oxides.

- Grinding- surface is grinding to remove all coating and to achieve precise dimension.

Assay

| Element | TYPE 361 |

|---|---|

| C | 0.01 wt%, max |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.01 wt%, max |

| Mo | Remainder (99.95% min.) |

Typical Size Available (Please inquire for details)

| Diameter,In. | Length, In. Max. |

|---|---|

| 0.08-8” | 100” |

Please refer to Mo Wire for smaller sizes, and Unwrought Molybdenum Rod for supralloys.

Mechanical Properties– ASTM B387 TYPE 361

| Thickness, in. (mm) | Tensile Strength,min, ksi (MPa) | Yield Strength, min, ksi (MPa) | Elongation min,% |

|---|---|---|---|

| 0.020 to 1⁄8 (0.51 to 3.18) | 85 (585) | 65 (450) | 15 |

| 1⁄8 to 13⁄32 (3.18 to 10.32) | 75 (515) | 55 (380) | 15 |

| 13⁄32 to 7⁄8 (10.32 to 22.2) | 90 (620) | 75 (515) | 18 |

| 7⁄8 to 11⁄8 (22.2 to 28.6) | 85 (585) | 70 (480) | 15 |

| 11⁄8 to 17⁄8 (28.6 to 47.6) | 75 (515) | 65 (450) | 10 |

| 17⁄8 to 27⁄8 (47.6 to 73.0) | 70 (480) | 60 (415) | 10 |

| 27⁄8 to 31⁄2 (73.0 to 88.9) | 65 (450) | 55 (380) | 10 |

Materials available for Molybdenum and Molybdenum Alloy Rod

Type 361 – Unalloyed powder metallurgy molybdenum.

Type 364 – Powder metallurgy molybdenum-0.5 % titanium-0.1 % zirconium (TZM) alloy.

Standard Packing

Wooden Boxes, Carton Boxes

| Physical Properties | Molybdenum (Atom#42) |

|---|---|

| Phase | Solid |

| Melting Point | 2896 K (2623°C, 4753°F) |

| Boiling Point | 4912 K (4639°C, 8382°F) |

| Heat of Fusion | 37.48 kJ/mol |

| Heat of Vaporization | 598 kJ/mol |

| Molar Heat Capacity | 24.06 J/(mol•K) |

| Atomic Weight | 95.95 |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |