| Product | Tungsten Silver Alloy (WAg) |

|---|---|

| Part Number | WAg |

| Synonyms | silver tungsten, tungsten silver, AgW, WAg |

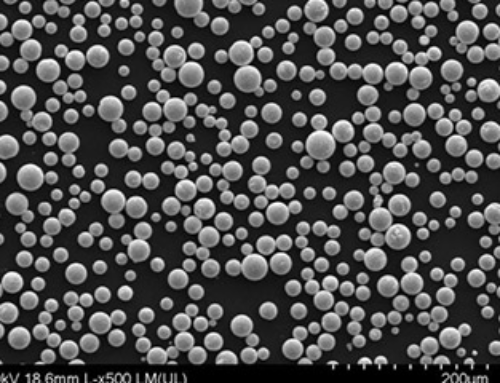

Tungsten silver alloy is a kind of two-phase structure pseudo alloy mainly composed of tungsten and silver. Because the physical properties of silver and tungsten are quite different, it can’t be produced by melting and casting. Instead, it is usually obtained by powder alloy technology. The technological process includes batching, mixing, pressing, sintering, melting, and cold working.

Tungsten silver alloy combines the advantages of metal tungsten and silver, among which tungsten has high melting point (tungsten point is 3410°C) and high density (tungsten density is 19.34 g/m3), while silver has excellent conductivity and thermal conductivity. Tungsten silver alloy (composition generally ranges from wcu7 to wcu50) has uniform microstructure, high temperature resistance, high strength, arc erosion resistance and high density.

Compared with W-Cu alloy, W-Ag alloy has better conductivity, plasticity and oxidation resistance, but lower strength and hardness, and higher price. Please refer to Tungsten Copper Page for our W-Cu products.

Applications:

Tungsten Silver Alloy is widely used in high temperature resistant materials, electrical alloy for high voltage switch, electrical processing electrode, microelectronic materials. As spare parts and components, it is widely used in aerospace, aviation, electronics, power, metallurgy, machinery, sports equipment and other industries.

Electrical industry:

Connectors, thermal conductors, switch accessories, electrical connectors, circuit breaker accessories, switch contacts, electronic equipment parts, etc.

Parts and consumables:

Resistance welding electrode, seam welding wheel, spot welding electrode, heat sink, EDM electrode, electric corrosion processing or electric contact processing, Need conductive high temperature resistant equipment parts, lightning protection equipment arcing base plate and fasteners, high voltage protection plate, counterweight, electronic packaging heat sink material, radiator, etc.

Order Information

Please include the following information with your inquires and orders:

- Dimensions / Drawings

- Quantity in weight, number of pieces

- Silver (Ag) Content

Typical Size Available (Please inquire for details)

| Item Code | Silver (wt%) | Total Impurities (%) max. | Tungsten (wt.%) | Denstity (g/cm³) | Hardness (HB) | Electrical Conductivity IACS%> |

| WAg70 | 70+/-2 | 0.5 | Remainder | 11.75 | 75 | 75 |

| WAg60 | 60+/-2 | 0.5 | Remainder | 12.40 | 85 | 66 |

| WAg50 | 50+/-2 | 0.5 | Remainder | 13.15 | 105 | 57 |

| WAg45 | 45+/-2 | 0.5 | Remainder | 13.55 | 115 | 54 |

| WAg40 | 40+/-2 | 0.5 | Remainder | 14.00 | 125 | 51 |

| WAg35 | 35+/-2 | 0.5 | Remainder | 14.50 | 135 | 48 |

| WAg30 | 30+/-2 | 0.5 | Remainder | 14.90 | 150 | 45 |

| WAg25 | 25+/-2 | 0.5 | Remainder | 15.40 | 165 | 41 |

| WAg20 | 20+/-2 | 0.5 | Remainder | 16.10 | 180 | 37 |

It can be supplied in the forms of sheets, plates, rods and Custom Shapes as per the drawing. Please refer to Tungsten Copper Page for our W-Cu products.

Standard Packing

Sealed bags or carton boxes.

Physical Properties – Tungsten Silver Alloy

| Physical properties | Tungsten (W) | Silver(Ag) |

| Density | 19.25 g/cm3 | 10.49 g/cm3 |

| Thermal expansion 10-6/°C | 4.5 | 19.5 |

| Thermal conductivity w/(m·k) | 174 | 429 |

| Boiling point °C | 3410 | 961 |

| Heat capacity J/(kg·°C) | 136 | 232 |

| Elastic Modulus Gpa | 411 | |

| Strength Mpa | 550 | 180 |