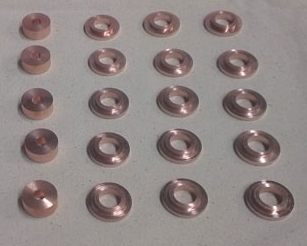

| Product | Tungsten Copper Switch Contact (CuW Electrical Contact) |

|---|---|

| Part Number | WCu-3 |

Tungsten copper alloy is a pseudo alloy composed of tungsten and copper. The copper content of the commonly used alloy is 10% – 50%. Tungsten copper electrical contact can withstand high temperature and high stress of nearly 2000 degrees, and has high melting point, high hardness, burn resistance and good adhesion resistance. Therefore, it is widely used in arresters, SF6 circuit breakers, high-pressure vacuum load switches, high-pressure superhydraulic electrical switches resistant to arc erosion.

One of the most important applications is the electrical contact used as the high-voltage electrical switch. The high-voltage electrical switch is small in volume, easy to maintain, and has a wide range of use. It can be used in humid, flammable, explosive and corrosive environment. It is required to be resistant to arc erosion, fusion welding, cut-off current, gas content and thermal electron emission.

The electrical contact material is the key component of high-voltage electrical appliances, which is responsible for making and breaking current, and directly affects the reliability and service life of switches and electrical appliances. In the process of arcing, the temperature of copper tungsten contact of high-voltage switch will rise to several thousand degrees Celsius in a few seconds. At this time, the copper in the tungsten copper alloy (melting point 1083°C) is liquefied and evaporated. Because of the capillary action, it is adsorbed in the capillary hole of the tungsten skeleton. Under the high temperature action of the arc, it evaporates and takes a lot of heat away, which reduces the surface temperature of the tungsten copper contact, so that the contact has good breaking performance. Because the melting point of tungsten is very high, the ablation in the arc is very small, even if the local temperature is too high, the fusion welding will not occur, thus ensuring the stability and reliability of the switch performance. The higher the content of tungsten in the tungsten copper alloy contact, the better the burn resistance, but the lower the conductivity, the specific use should be selected.

Applications

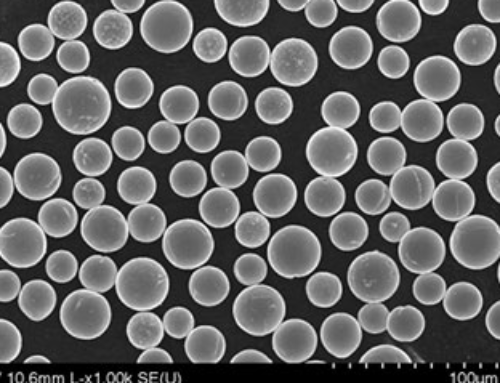

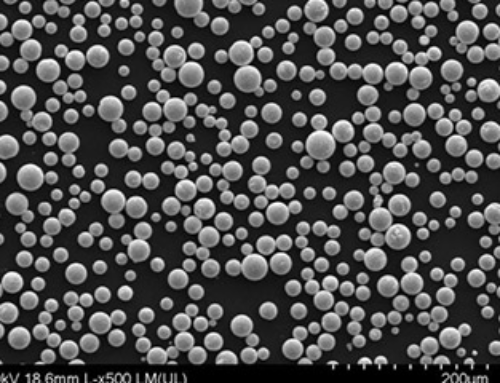

In addition to conventional high-voltage electrical switches, the main development of tungsten copper materials for electrical contacts is as follows. First, the development of tungsten copper electrical contacts for ultra-high voltage is from 500000 volts to 750000 volts or even more than 2 million volts; Second, vacuum tungsten copper materials for medium voltage. As the contact material of tungsten copper for vacuum, in addition to the performance required by the conventional electrical contact, it is required to meet the extremely low gas content of the material in the vacuum application, which requires special manufacturing processes, such as high temperature or vacuum degassing, vacuum infiltration, etc. Different from the traditional tungsten copper contact materials, the vacuum tungsten copper contact materials have developed tungsten copper products with high tungsten and low copper content, such as wcu10, wcu15, etc. For some tungsten copper materials with low cutoff value, a small amount of ternary metals such as antimony, bismuth and tellurium can be added.

Tungsten copper switch contact can be used as moving arc contact, static arc contact, conducting rod, shielding cover, and various special-shaped contacts, etc., which are respectively applied to GIS and GCB products with different voltage levels of 35 kv and 1000 kv.

Order Information

Please include the following information with your inquires and orders:

- Dimensions / Drawings

- Quantity in weight, number of pieces

- Copper Content

Physical and mechanical properties of tungsten copper alloy

| Item Code | Copper(wt.%) | Tungsten(wt.%) | Denstity (g/cm³) | Hardness (HB) | Electrical conductivity IACS%> |

| CuW50 | 50+/-2 | Remainder | 11.85 | 110 | 54 |

| CuW55 | 45+/-2 | Remainder | 12.30 | 125 | 49 |

| CuW60 | 40+/-2 | Remainder | 12.75 | 140 | 47 |

| CuW65 | 35+/-2 | Remainder | 13.30 | 155 | 44 |

| CuW70 | 30+/-2 | Remainder | 13.80 | 175 | 42 |

| CuW75 | 25+/-2 | Remainder | 14.5 | 195 | 38 |

| CuW80 | 20+/-2 | Remainder | 15.15 | 220 | 34 |

| CuW85 | 15+/-2 | Remainder | 15.9 | 240 | 30 |

| CuW90 | 10+/-2 | Remainder | 16.75 | 260 | 27 |

It can be supplied in the forms of sheets, plates, rods and Custom Shapes as per the drawing. Please refer to our Tungsten Copper Alloys for the Electronic packaging material and Tungsten copper heat sink.

Standard Packing

Sealed Bags or Carton Boxes.

Physical Properties – Tungsten Copper Alloy

| Physical properties | Tungsten (W) | Copper (Cu) |

| Density | 19.25 g/cm3 | 8.92 g/cm3 |

| Thermal expansion 10-6/°C | 4.5 | 16.6 |

| Thermal conductivity w/(m·k) | 174 | 403 |

| Boiling point °C | 3410 | 1083 |

| Heat capacity J/(kg·°C) | 136 | 385 |

| Elastic Modulus Gpa | 411 | 145 |

| Strength Mpa | 550 | 120 |