| Product | Tungsten Copper Electrode (WCu Electrode) |

|---|---|

| Part Number | WCu-2 |

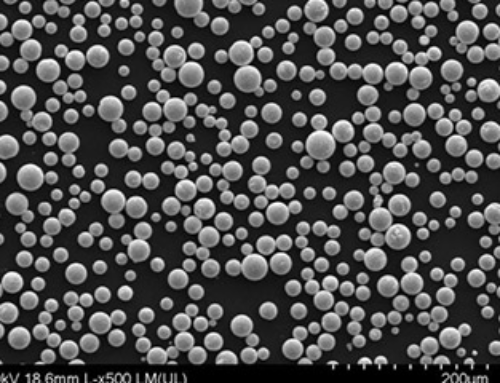

Tungsten copper electric spark electrode is a two-phase structure pseudo alloy composed of tungsten element as the base and copper element as the auxiliary. It is made of fine high-purity tungsten powder and high-purity tungsten copper powder by the first-class process of mixed powder hydrostatic forming high-temperature sintering solution copper.

Tungsten copper electrode has both high temperature resistance of tungsten and high conductivity of copper, which makes it not only have good arc breaking performance, good conductivity and heat conduction, small thermal expansion, high temperature without softening, but also arc corrosion resistance, high wear resistance, long service life and low correction electrode rate. So it is an ideal advanced electrode material.

Application:

Tungsten copper alloy electrode has the advantages of high electric corrosion rate, low loss rate, precise electrode shape, excellent processing performance, and good surface quality of processed parts. As parts and components, it is widely used in aerospace, aviation, electronics, power, metallurgy, machinery, medical equipment and other industries. It can be used for the EDM electrode and Resistance welding electrode.

EDM electrode (electrical discharge machining, EDM) can be made of the tungsten copper alloy, which has the advantages of high conductivity, high melting point and small thermal expansion. In the EDM process, the electrode is used to transmit the machining pulse and etch the workpiece with its own minimum loss. Because of its excellent machining performance, EDM can effectively save electrode materials, improve the speed of EDM and improve the accuracy of die, and thus save the cost of machining tools and maintenance costs.

Order Information

Please include the following information with your inquires and orders:

- Dimensions / Drawings

- Quantity in weight, number of pieces

- Copper Content

Physical and Mechanical Properties of Tungsten Copper Alloy

| Item Code | Copper(wt.%) | Tungsten(wt.%) | Denstity (g/cm³) | Hardness (HB) | Electrical conductivity IACS%> |

| CuW50 | 50+/-2 | Remainder | 11.85 | 110 | 54 |

| CuW55 | 45+/-2 | Remainder | 12.30 | 125 | 49 |

| CuW60 | 40+/-2 | Remainder | 12.75 | 140 | 47 |

| CuW65 | 35+/-2 | Remainder | 13.30 | 155 | 44 |

| CuW70 | 30+/-2 | Remainder | 13.80 | 175 | 42 |

| CuW75 | 25+/-2 | Remainder | 14.5 | 195 | 38 |

| CuW80 | 20+/-2 | Remainder | 15.15 | 220 | 34 |

| CuW85 | 15+/-2 | Remainder | 15.9 | 240 | 30 |

| CuW90 | 10+/-2 | Remainder | 16.75 | 260 | 27 |

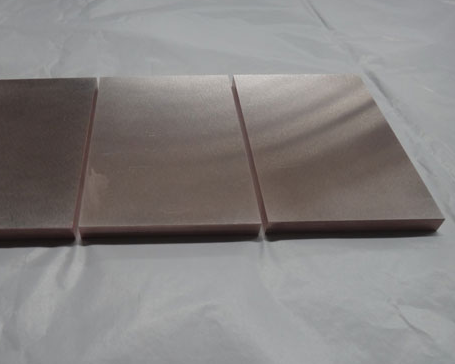

It can be supplied in the forms of sheets, plates, rods and Custom Shapes as per the drawing. Please refer to our Tungsten Copper Alloy for the Electronic packaging material and Tungsten copper heat sink.

Standard Packing

Sealed Bags or Carton Boxes.

Physical Properties – Tungsten Copper

| Physical properties | Tungsten (W) | Copper (Cu) |

| Density | 19.25 g/cm3 | 8.92 g/cm3 |

| Thermal expansion 10-6/°C | 4.5 | 16.6 |

| Thermal conductivity w/(m·k) | 174 | 403 |

| Boiling point °C | 3410 | 1083 |

| Heat capacity J/(kg·°C) | 136 | 385 |

| Elastic Modulus Gpa | 411 | 145 |

| Strength Mpa | 550 | 120 |