| Product | Tungsten Carbide (WC) Powder |

| Part Number | TRM-WCP |

| EINECS | 235-123-0 |

| CAS Number | 12070-12-1 |

Typical application: Tungsten Carbide (WC) Powder is used as high speed cutting tools, kiln structure materials, jet engine components, metal ceramic materials, resistance heating elements and so on. It is used for making cutting tools, wear-resistant parts, copper, cobalt, bismuth and other metal melting crucibles, and wear-resistant semiconductor films. It is used as a super hard tool material and a wear-resistant material. It can form solid solution with many carbides.

Features and Relative Products:

- Please refer to Tungsten Powder.

- Please refer to Tungsten Trioxide Powder.

Order Information

Inquiries and orders should include the following information:

1. Quantity

2. Particle Size

Chemical Composition – Tungsten Carbide Powder

| Carbon Content % | Total Carbon | 6.13 +/- 0.05 |

| Combined Carbon | 6.07 min. | |

| Free Carbon | 0.06 max. | |

| Impurities % max. | Mo | 0.005 |

| Al | 0.002 | |

| Ca | 0.002 | |

| Si | 0.003 | |

| Co | 0.01 | |

| Si | 0.002 | |

| P | 0.005 | |

| As | 0.005 | |

| K+Na | 0.003 | |

| Cr | 0.03 | |

| Fe | 0.02 | |

| Mg | 0.002 | |

| Mn | 0.001 | |

| Ni | 0.008 |

*Special Requirements are available on request.

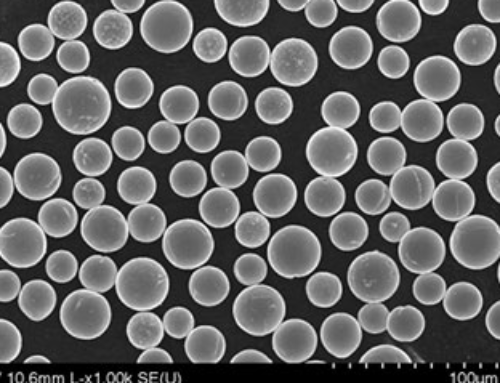

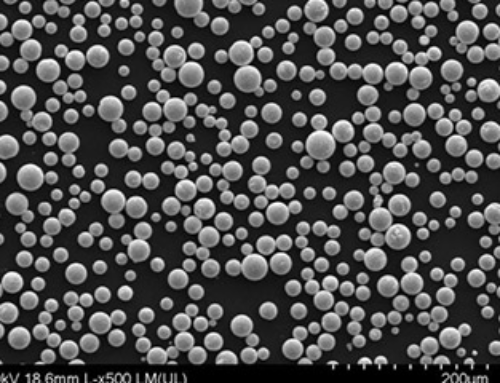

Particle Size And Oxygen Content

| Item Code | FSSS (µm) | Oxygen Content (%) Max. |

| WCP-01 | 1.01-1.40 | 0.15 |

| WCP-02 | 1.41-1.80 | 0.1 |

| WCP-03 | 1.81-2.40 | 0.1 |

| WCP-04 | 2.41-3.00 | 0.08 |

| WCP-05 | 3.01-4.00 | 0.08 |

| WCP-06 | 4.01-5.00 | 0.08 |

| WCP-07 | 5.01-7.00 | 0.05 |

| WCP-08 | 7.01-10.00 | 0.05 |

| WCP-09 | 10.01-14.00 | 0.05 |

| WCP-10 | 14.01-20.00 | 0.05 |

| WCP-11 | 20.01-26.00 | 0.05 |

*Custom work is available on request.

Standard Packing

Packed in iron drums of 25 kg or 50 kg net each with inner double plastic bags. Special package is available on request.

Physical Properties – Tungsten Carbide (WC) Powder

| Form | Powder |

|---|---|

| Color | Light gray or dark gray |

| Melting Point | 2870°C |

| Boiling Point | 6000°C |

| Relative Density (Specific Gravity) | 15.63 g/cm3 |