| Product | Tantalum Tungsten Rod / Bar (Ta-W Rod/ Ta-W Bar) |

| Part Number | TRM-TA009 |

| Standard | ASTM B365 UNS R05252/ UNS R05255 |

| Assay | Ta97.5W2.5 or Ta90W10 |

| Density | 16.9 g/cm3 |

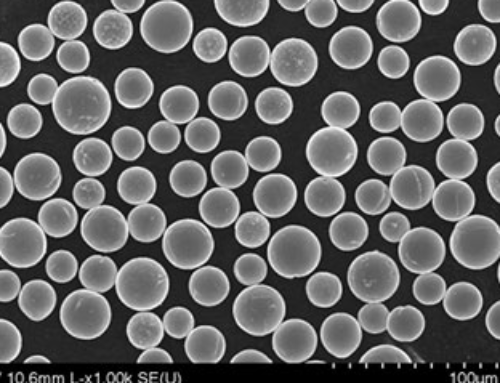

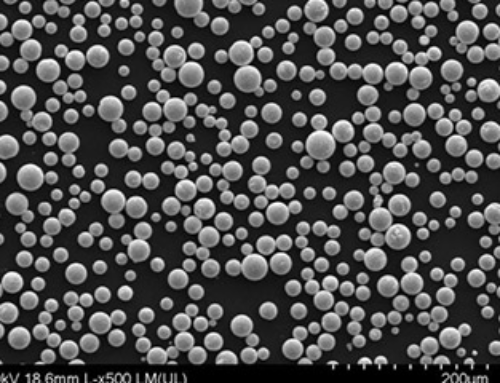

Tantalum tungsten alloy (Ta-W alloy) is typically tantalum 2.5% Tungsten and tantalum 10% Tungsten of high density 16.90 g/cm3. It has good high-temperature mechanical properties, high density, high strength, good toughness and strong stiffness, and the working temperature can be up to 1500°C. In addition, tantalum tungsten alloy rod has excellent corrosion resistance. We can offer a wide variety of diameters.

Application: Tantalum tungsten alloy rod is used for chemical process equipment including heating and cooling coils, heat exchange, condensers, reaction vessels, leaf springs and bellows.

Assay

| Element | UNS R05252 | UNS R05255 |

|---|---|---|

| O | 0.015% max | 0.015% max |

| C | 0.010% max | 0.010% max |

| N | 0.010% max | 0.010% max |

| H | 0.0015% max | 0.0015% max |

| Fe | 0.010% max | 0.010% max |

| Ni | 0.010% max | 0.010% max |

| Si | 0.005% max | 0.005% max |

| Ti | 0.010% max | 0.010% max |

| Mo | 0.020% max | 0.020% max |

| W | 2.0-3.5% max | 9.0-11.0% max |

| Nb | 0.50% max | 0.10% max |

| Ta | Remainder | Remainder |

UNS Grade R05252—Tantalum + 2.5% tungsten alloy, vacuum melted.

UNS Grade R05255—Tantalum + 10% tungsten alloy, vacuum melted.

Typical Size Available (Please inquire for details)

| Dimensions | Range | Typical Tolerance |

|---|---|---|

| Diameter | 1” to 8” | +/-0.03” |

| Length | On request | Plus Tolerance |

Please refer to Tantalum Tungsten Alloy Wire for smaller sizes.

Order Information

Please include the following information with your inquires and orders:

1. Quantity

2. Dimensions

3. Ta90W10 or Ta97.5W2.5

Materials available for Tantalum and Tantalum Alloy Rod

R05400—Unalloyed tantalum, powdermetallurgy consolidation,

R05200—Unalloyed tantalum, vacuum melted,

R05252—Tantalum + 2.5% tungsten alloy, vacuum melted.

R05255—Tantalum + 10% tungsten alloy, vacuum melted.

Mechanical Properties for Tantalum Tungsten Alloy Rod

| Mechanical Properties | Ultimate tensile strength, min, psi | Yield Strength,min, psi (MPa) | Elongation, min % |

|---|---|---|---|

| 97.5% tantalum 2.5% tungsten (R05252) | 40 000 (276) | 28 000 (193) | 20 |

| 90% tantalum 10% tungsten (R05255) | 70 000 (482) | 55 000 (379) | 20 |