Nitinol (nickel titanium alloy) is an alloy composed of nickel and titanium. Due to the change of temperature and mechanical pressure, there are two different crystal structure phases, i.e. austenite phase and martensite phase. The transformation sequence of NiTi alloy is parent phase (austenite phase) – R phase – martensite phase. The R phase is rhombohedral and austenite is the state when the temperature is higher (greater than As, the temperature at which austenite starts to form), or when the load is removed (deactivation by external force), cubic and hard. The shape is relatively stable. The martensite phase is a state with relatively low temperature (less than Mf: the temperature at which the transformation to martensite is complete) or when loaded (activated by external force). It is hexagonal, ductile, repetitive, unstable and easy to deform.

Nitinol is a kind of functional material. In addition to high specific strength, wear resistance, corrosion resistance, non-magnetic, good biocompatibility and other characteristics, it also has unique shape memory properties and super elastic properties. It is widely used in aerospace, communication, medical industry, automatic control, instrumentation, pipeline connection, glasses manufacturing and daily life.

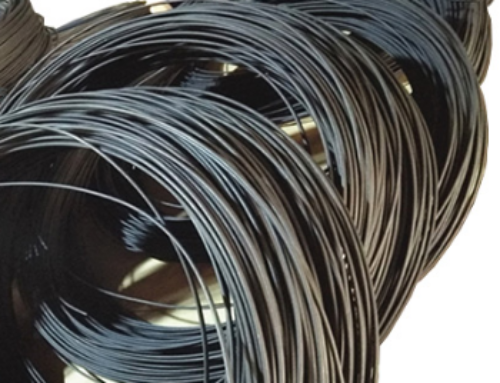

TRM can provide Nitinol Wire as required. Please contact us for more details.

Special properties of Nitinol (NiTi):

- Shape memory

- Superelasticity

- Sensitivity to intraoral temperature changes

- Excellent corrosion resistance

- Anti-toxicity

- Gentle correction force

- Good damping properties

Superelasticity refers to the phenomenon that the strain produced by the specimen under the action of external force is much larger than its elastic limit strain, and the strain can recover automatically when unloading. That is, in the parent phase state, due to the effect of external stress, the stress-induced martensitic transformation occurs, so the alloy exhibits a mechanical behavior different from that of ordinary materials. Its elastic limit is far greater than that of ordinary materials, and it no longer complies with Hooke’s law. Compared with shape memory properties, superelasticity has no thermal involvement. In a word, superelasticity refers to that the internal stress does not increase with the increase of strain in a certain deformation range.

Shape memory characteristic is that when the parent phase of a certain shape is cooled from above Af temperature to below Mf temperature to form martensite, the martensite is deformed at the temperature below Mf and heated to below Af temperature. With reverse phase transformation, the material will automatically recover its shape in the parent phase. In fact, shape memory effect is a thermally induced phase transformation process of NiTi alloy.

Typical Chemical Composition (%)

| Ti | Ni | Cr | Cu | Nb |

| Balance | 54.5-57.0 | ≤0.01 | ≤0.01 | ≤0.025 |

| C | Fe | Co | N+O | H |

| ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.005 |

Typical Specs of Nitinol Wire

| Dimensions | Typical diameter ≥0.05 mm |

| Category | Superelastic wire or shape memory wire (drawing required) |

| Af Temperature | As required (ranges from -15°C to 100°C, room temperature is commonly used) |

| Spec. | ASTM F2063 if requried |

| Surface | Bright, black oxidation, polished, light oxidation (gold, brown, red, blue or others), or others as requested. |

| Packing | Spools or straight |

| Production Process | Hot or cold drawn |

| Typical Applications | Guide wire, dental arch wire, dental root canal files, glass frames, antennas, fishing gears, jewelry, toys and etc. |

Order Information

Please include the following information with your inquires and orders:

- Quantity

- Dimensions or drawings

- Application/ Af temperature

- Special requirements, if any

Standard Packing

Standard Packing: Carton boxes or wooden boxes.