| Product | Molybdenum Crucible (Mo Crucible) |

|---|---|

| Part Number | TRM-MO014 |

| Purity | 99.95% |

| Type | Seamless or Welded |

| Density | 10.2 g/cm3 |

| CAS# | 7439-98-7 |

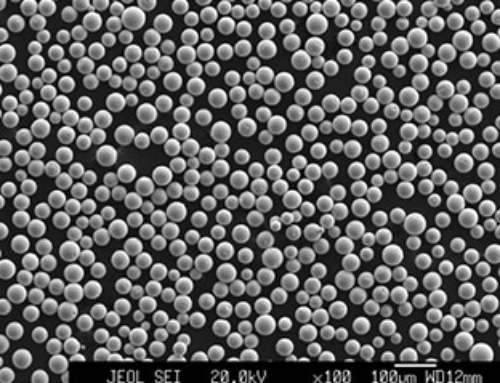

Molybdenum crucible is usually made from the pure molybdenum powder with purity up to 99.95%. The density of molybdenum crucible is more than 9.8 g/cm3, and its working temperature ranges from 1100℃ to 1700℃ in the vacuum environment.

The lid is not always necessary, but the molybdenum crucible can be manufactured with a lid to be a set. The lids can have different shapes, like a round one with a hole in the middle. For the application of melting metal, it should be sloping placing for oxygen exchanging to prevent fluid inside from spraying. Please refer to the Mo Sheet for other Molybdenum products.

Application: Molybdenum crucible is widely used in the core container of the sapphire single crystal growth furnace, the quartz glass melting furnace, the rare earth smelting furnaces, the metallurgical industry and etc.

Order Information

Please include the following information with your inquires and orders:

1. Quantity

2. Dimensions

3. Welded or Seamless

Assay

| Element | Purity: 99.95% |

|---|---|

| C | 0.01 wt%, max |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.01 wt%, max |

| Mo | Remainder |

Standard Packing

Wooden Boxes, Carton Boxes

Typical Size Available (Please inquire for details)

Sintered Molybdenum Crucible

It undergoes the pressing, sintering and machining. And it can be offered in large sizes. The density is 9.5-9.8 g/cm3.

The outer diameter ranges from 0.4’’ to 20’’ and the height ranges from 0.4’’ to 23.5’’.

Forging Molybdenum Crucible

It undergoes the pressing, sintering, forging and machining. The molybdenum crucible is produced by a forging press to achieve the size, mechanical properties, and shapes. The density is 10.1 g/cm3 min.

The outer diameter ranges from 0.4’’ to 5’’ and the height ranges from 0.4’’ to 7.8’’.

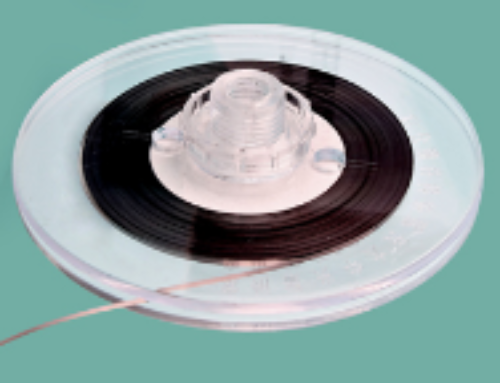

Welded Molybdenum Crucible

It is produced by welding process, which can lower the cost. However, since the weldability of the molybdenum is not good, the wall thickness can not be very thick and the air tightness is not high.

It’s now widely used in Bridgman-Stockbarge method single crystal growth furnace. We can supply 2’’,4’’ and 6’’ Welded Molybdenum Crucibles.

| Physical Properties | Molybdenum (Atom#42) |

|---|---|

| Phase | Solid |

| Melting Point | 2896 K (2623°C, 4753°F) |

| Boiling Point | 4912 K (4639°C, 8382°F) |

| Heat of Fusion | 37.48 kJ/mol |

| Heat of Vaporization | 598 kJ/mol |

| Molar Heat Capacity | 24.06 J/(mol•K) |

| Atomic Weight | 95.95 |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |