| Product | Tungsten Copper Alloy (WCu) |

|---|---|

| Part Number | WCu-1 |

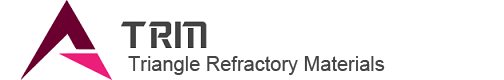

Tungsten copper alloy, also called Copper tungsten alloys, short for WCu/CuW, refers to the alloy composed of tungsten and copper. The copper content of commonly used alloys is 10% – 50%. The alloy is made by powder metallurgy, which has good conductivity, good high temperature strength and certain plasticity. At a very high temperature, such as over 3000°C, copper in the alloy is liquefied and evaporated, which absorbs a lot of heat and reduces the surface temperature of the material. So this kind of material is also called metal sweating material.

Tungsten copper alloy has a wide range of applications. It is mainly used to manufacture high-temperature components such as contacts of high-voltage electrical switches resistant to arc erosion, throat linings of rocket nozzles, tail rudders, etc. it is also used as electrodes for electrical processing, high-temperature molds and other occasions requiring conductive and thermal conductivity and high-temperature use.

Application: Tungsten copper widely used as the contact and protection ring of high-voltage, superhydraulic switch and circuit breaker, as the raw anvil block material of electric heating pier, as the conductive tip of automatic submerged arc welding, as the nozzle of plasma cutting machine, as the welding head of electric welding machine, as the welding head of butt welding machine, as well as the welding roller, as the sealing gas socket electrode and spark electrode, as the materials of spot welding and butt welding, etc.

Order Information

Please include the following information with your inquires and orders:

- Dimensions / Drawings

- Quantity in weight, number of pieces

- Copper Content

Electronic packaging material

It has both the low expansion property of tungsten and the high thermal conductivity property of copper. Its thermal expansion coefficient and thermal conductivity can be changed by adjusting the composition of the material.

In recent years, with the development of high power electronic devices and large-scale integrated circuits, the requirements of electronic packaging materials are higher and higher. As electronic packaging and heat sink materials, there are higher requirements for the quality and performance of tungsten copper materials, which not only require high purity and uniform structure, good air tightness (high density), low gas content (good vacuum performance), but also higher conductivity and thermal conductivity and strictly controlled thermal expansion coefficient.

Tungsten copper heat sink

It is mainly used in electronic devices with high performance, high integration and high reliability. It matches with electronic materials such as Si, GaAs, Al2O3 and be and plays the role of heat dissipation, support and protection. At present, tungsten copper heat sink and tungsten copper packaging materials have been widely used in high-power pulse microwave tubes, laser diodes, integrated circuit modules, power electronic devices, MCM, CPU and other components.

Performance requirements for tungsten copper electronic packaging and heat sink materials

| Item Code | Copper(wt.%) | Tungsten(wt.%) | Denstity (g/cm³) | Thermal conductivity (W/m2·K) | Thermal expansion (×10-6/K) |

| WCu10 | 10+/-2 | Remainder | 16.75 | 160-180 | 6.3-6.8 |

| WCu15 | 15+/-2 | Remainder | 15.9 | 180-200 | 7.0-7.5 |

| WCu20 | 20+/-2 | Remainder | 15.15 | 190-210 | 8.0-8.5 |

| WCu25 | 25+/-2 | Remainder | 14.5 | 200-230 | 9.0-9.5 |

| WCu30 | 30+/-2 | Remainder | 13.8 | 240 | 9.7 |

It can be supplied in the forms of sheets, plates, rods and Custom Shapes as per the drawing. For the Electrode products, please refer to our Tungsten Copper Electrode.

Standard Packing

Sealed Bags or Carton Boxes

Physical Properties – Tungsten Copper Alloy (WCu)

| Physical properties | Tungsten (W) | Copper (Cu) |

| Density | 19.25 g/cm3 | 8.92 g/cm3 |

| Thermal expansion 10-6/°C | 4.5 | 16.6 |

| Thermal conductivity w/(m·k) | 174 | 403 |

| Boiling point °C | 3410 | 1083 |

| Heat capacity J/(kg·°C) | 136 | 385 |

| Elastic Modulus Gpa | 411 | 145 |

| Strength Mpa | 550 | 120 |