| Product | Molybdenum Tube (Mo Tube, Mo Pipe) |

|---|---|

| Part Number | TRM-MO005 |

| Purity | 99.95% |

| Type | Seamless or Welded |

| Density | 10.2 g/cm3 |

| CAS# | 7439-98-7 |

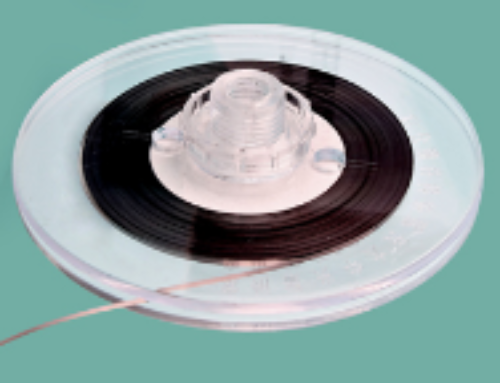

Molybdenum tube has the low vapor pressure and the high melting point. And it is suitable for the heat-shield tubes under high temperatures. In recent years, Molybdenum is also applied for the rotary sputtering targets. We can offer molybdenum tubes in various dimensions. The tubes are seamless or welded, with the purity up to 99.95%. Please contact us for more details.

Application: Used for the semiconductors, medical devices, furnace parts, and sputtering targets.

Order Information

Please include the following information with your inquires and orders:

1. Quantity

2. Dimensions

3. Welded or Seamless

Assay

| Element | TYPE 361 |

|---|---|

| C | 0.01 wt%, max |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.01 wt%, max |

| Mo | Remainder (99.95% min.) |

Typical Size Available (Please inquire for details)

| Outer Diameter(OD), In. | Inner Diameter(ID), In. | Length(L), In. Max. |

|---|---|---|

| 0.28” | 0.16” | 4” |

| 2” | 1.58” | 45” |

| 5.7” | 5” | 115” |

Materials available for Molybdenum and Molybdenum Alloy Tube

Type 361 – Unalloyed powder metallurgy molybdenum.

Type 364 – Powder metallurgy molybdenum-0.5% titanium-0.1% zirconium (TZM) alloy.

Standard Packing

Wooden Box or Carton Box.

| Physical Properties | Molybdenum (Atom#42) |

|---|---|

| Phase | Solid |

| Melting Point | 2896 K (2623°C, 4753°F) |

| Boiling Point | 4912 K (4639°C, 8382°F) |

| Heat of Fusion | 37.48 kJ/mol |

| Heat of Vaporization | 598 kJ/mol |

| Molar Heat Capacity | 24.06 J/(mol•K) |

| Atomic Weight | 95.95 |

| Thermal Conductivity | 1.38 W/cm/K @ 298.2 K |