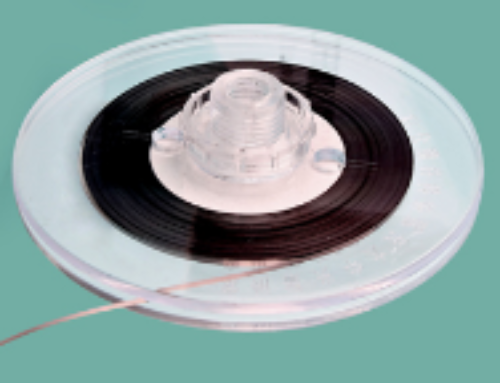

| Product | Titanium Zirconium Molybdenum Foil (TZM Foil, TZM Strip) |

|---|---|

| Part Number | TRM-MO025 |

| Standard | ASTM B386 TYPE 364 |

| Surface | As rolled |

| Density | 10.22 g/cm3 |

Titanium Zirconium Molybdenum Alloy is so-called TZM alloy, and it refers to the molybdenum – 0.5% titanium – 0.1% zirconium alloy. This alloy has better welding performance and higher strength/hardness. TRM can offer TZM foil or TZM strips in various dimensions in coils. Please contact us for more details.

Application: TZM foil is used as the high-temperature furnace components, nozzles, casting molds, rotating anodes, etc.

Order Information

Please include the following information with your inquires and orders:

1. Quantity in weight, or the number of pieces

2. Dimensions

3. Packing or Surface if there is anything special.

Assay

| Element | TYPE 364 |

|---|---|

| C | 0.01-0.04 wt% |

| Fe | 0.01 wt%, max |

| Ni | 0.005 wt%, max |

| Si | 0.005 wt%, max |

| Ti | 0.4-0.55 wt% |

| Zr | 0.06-0.12 wt% |

| Mo | Remainder |

Typical Size Available (Please inquire for details)

| Thickness, In. | Width, In. Max. | Length , In. Max. |

|---|---|---|

| < 0.004 | 5.5 | L |

| 0.004-0.008 | 10 | 40 |

Please refer to TZM Sheet for larger sizes.

Mechanical Properties– ASTM B386 TYPE 364

| Thickness, in. (mm) | Tensile Strength,min, ksi (MPa) | Yield Strength, min, ksi (MPa) | Elongation min,% |

|---|---|---|---|

| 0.010 to 0.025 (0.25 to 0.635) | 120 (830) | 100 (690) | 6 |

| 0.025 to 0.060 (0.635 to 1.5) | 120 (830) | 100 (690) | 7 |

| 0.060 to 0.090 (1.5 to 2.3) | 120 (830) | 100 (690) | 9 |

Materials available for Molybdenum and Molybdenum Alloy Foil/Strip

Type 361 – Unalloyed powder metallurgy molybdenum.

Type 364 – Powder metallurgy molybdenum – 0.5% titanium – 0.1% zirconium (TZM) alloy.

Standard Packing

Wooden Boxes, Carton Boxes, or Special packing is agreed upon by both parties.

| Physical Properties | TZM |

|---|---|

| Phase | Solid |

| Melting Point | 2617°C |

| Boiling Point | 4612°C |

| Thermal Conductivity | 126 W/m.K |